MONDAY 6TH JANUARY

We have a week left before our deadline and still theres much to do. Most important of all is making the glowworm cave, since that is the climax of the experience that we want to wonder Jason with in virtual and physical form. With more than half of my group sick or unavailable, I've come into uni almost every day from close to finish to complete the model and other parts of the project (i.e the presentation) along with Alex who's focusing on Twin motion. At practically every stage something put me to the test - it went wrong, malfunctioned or interfered - in which I had to constantly come up with fast solutions.

I designed the model cave from scratch and I wanted it to glow somehow. Figuring that out was hard - I considered purchasing fiberoptic strands which would have been very effective but expensive. Glow in the dark paint? Nah it wont show well during the presentation.

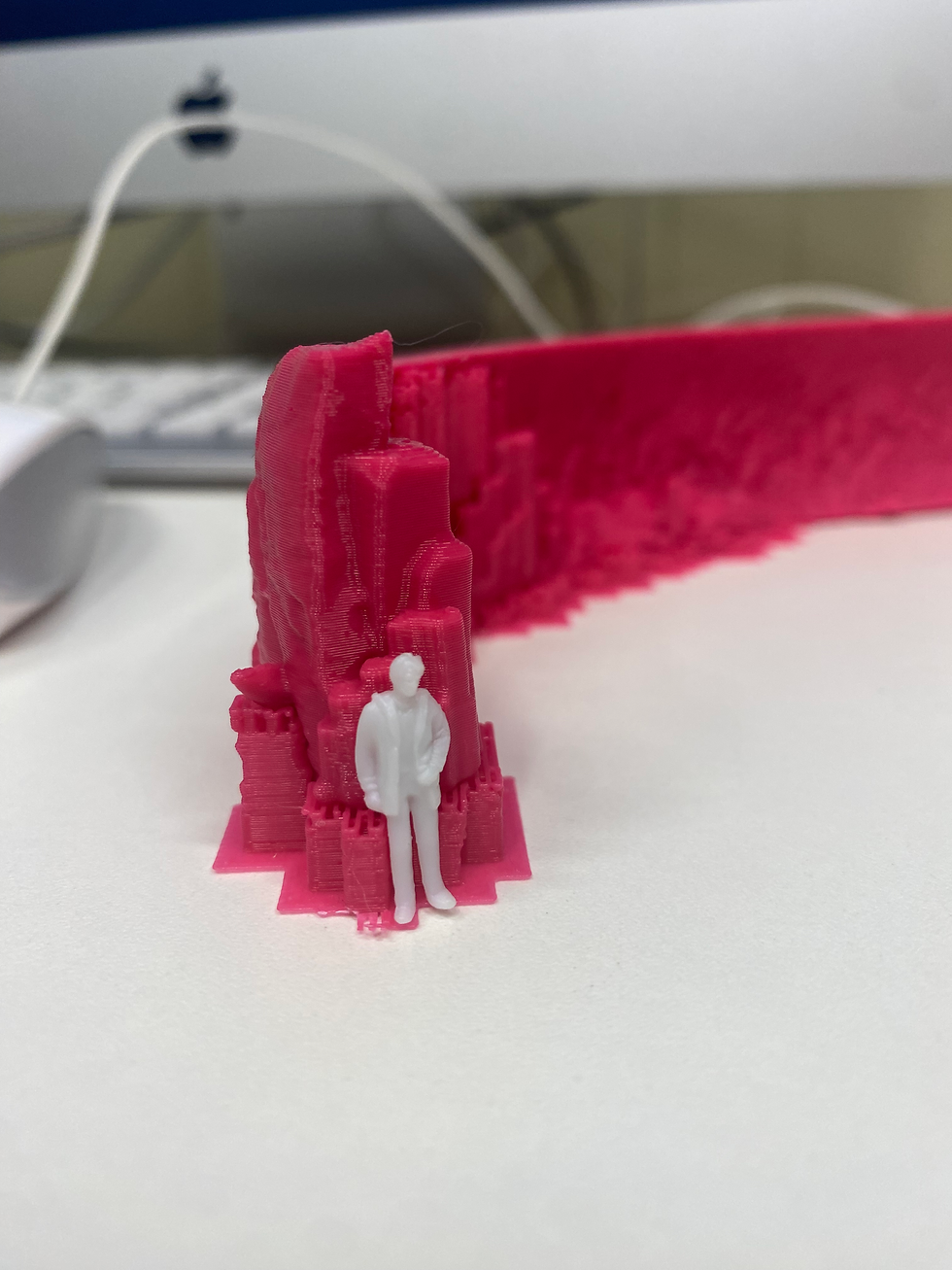

I settled with the idea of an LED compartment, where the light peaks through tiny holes in the lid structure, which recreates the gloworm effect.

FRIDAY 10TH

Today is the final day we can come into class before the deadline, so arrived at 8 o-clock sharp to get the rest of the cave printed as I multitask, so that by Monday it is painted and done. I soon realised I really messed up, thinking it would take less than 12 hours when it's actually 14 in total to print both pieces! longer than the whole school day. So in 2-3 I messed around, researched, sent dozens of emails to myself, running back and forth to the computer room 50 times, trying to reduce the printing without wasting any more of the valuable time I have left.

I feel like in those crazy few hours, I gained a year's worth of Bambu knowladge with the amount of pressure I was under, and it payed off.

SATURDAY 11TH

SATURDAY 11TH

The fact that it' s 3D printed with an installed light source provides Therme insight as to how to actually build it. When thinking about it architecturally, people can already 3D print houses and large structures, like caves, sustainably https://www.thisiscolossal.com/2022/09/living-3d-printed-walls/

Instead of unethically using real bioluminescent creatures or harmful materials, you can harness a small amount of light, both natural or electric, using a smart complex 3D printed structure consisting of a tunnel system of - holes - layers - filters - and non toxic glowing paint - similar to my little model. This saves a lot of electricity and resources which is good for everyone and the planet.

I'd like to think Therme will create our Biome with a balance of artificiality, naturally derived/sustainable elements and intelligent design. Horticulturalists working with Bio Engineers working with Architects working with Zoologists, Technologists, Psychologists, Artists. Using this kind of Hybrid method where diverse practices collaborate can be the key to the future and Therme most definitely has what it takes to do it.

I believe that so much resources and money is wasted on careless design; like the typical 20-1000 lights fitted into a ceiling, or metals/plastics /wood in areas where it's unnecessary. There are always better ways to build!

SUNDAY 12TH

HOW I'VE MANAGED TOWARDS THE DEADLINE